I posted this not long ago: https://www.madbeanpedals.com/forum/index.php?topic=32813.msg315471#msg315471

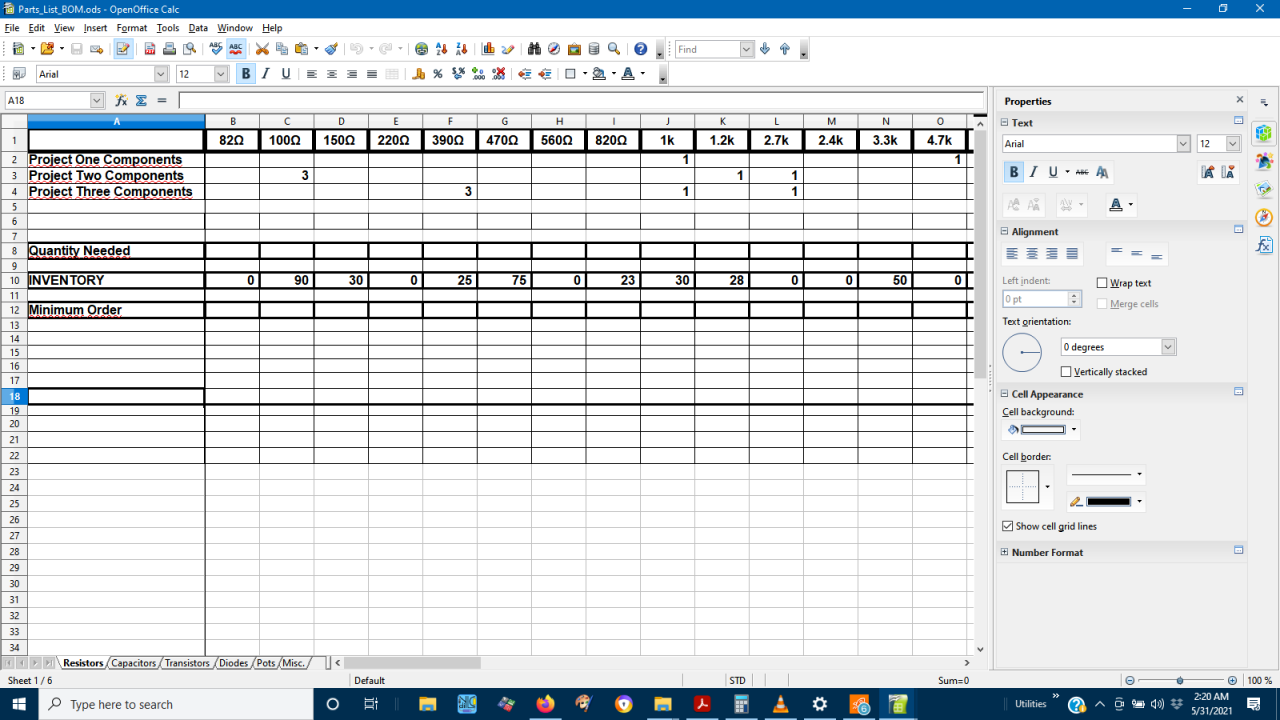

Created in Open Office, but there is an Excel version in the zip

Created in Open Office, but there is an Excel version in the zip

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

Show posts Menu

Quote from: peAk on April 16, 2021, 03:28:55 PMI got my second shot about 18 hours ago,

Got second dose of Moderna on Wednesday.

Feeling fairly crummy, little aches and chills, but nothing too bad.

First shot didn't get any side effects

Quote from: jubal81 on March 15, 2021, 11:16:47 PMGot the Moderna today (yesterday)

Got the Moderna and the first shot made my arm pretty sore the next two days and i felt barely a little funky the next day.

Getting my second dose on April 3. My wife was pretty down for a day after her second dose of Moderna.

I'm finally feeling a bit optimistic. I'll be considered fully vaccinated on the 17th of April and we're going to try to get some Mariners tickets for that weekend. WooHoo!

Quote from: culturejam on March 03, 2021, 06:00:56 AM

My wife got her second shot about a week ago. I'm on the wait list for the first shot. No telling when I'll get the call.

Quote from: peAk on December 20, 2020, 11:33:22 AMI must admit, I didn't read your entire post.Quote from: CodeMonk on December 19, 2020, 10:11:52 PM

I ordered some off of Amazon from a company called Hayes Paper Company...

https://www.amazon.com/Hayes-Paper-Waterslide-Water-Slide-Printable/dp/B07F26V391/ref=pd_rhf_ee_s_rp_c_2_0_4/141-2835431-3456007?_encoding=UTF8&pd_rd_i=B07F26V391&pd_rd_r=4b669a03-e5ad-4b58-8f44-31392626bb17&pd_rd_w=twbph&pd_rd_wg=l2iV0&pf_rd_p=45ea3989-28e2-45c9-97ac-7e99f613a91b&pf_rd_r=BPJ3VS2QZ7VA4T5Z7HVS&psc=1&refRID=BPJ3VS2QZ7VA4T5Z7HVS

Haven't tried it yet, so I can't speak for the quality. But that company came up high on a review/comparison of several different waterslide decal manufacturers.

read my original post, hopefully it (Hayes) works better for you than it did for me. I, too, was excited by the reviews but the stuff just didnt work great for me. After I had such a bad experience, I went back to the reviews and read some of the negative reviews and it seems they were describing some of the exact issues I was having. Basically whether you leave in the water for 10 second or even 60 seconds, the backing doesnt come off well and the decal begins to deform and basically become mush before you get it off. It's possible its a batch issue so hopefully you will have better luck. If you run into the same thing and figure out a solution, I am all ears. I still have 14 sheets of this stuff left.

edit: just to be clear, the Hayes I used was the clear waterslide, not the white like you linked. You may have better results.

I went ahead and ordered some Sunnyscopa and will give that a go.

Thanks for the recommendations, guys.

Quote from: mjg on October 12, 2020, 10:32:58 PMThe link: https://www.hakko.com/english/tip_selection/type_r.html

How does that type R tip work - does the solder paste hold the component in place? I'd be worried that I'd miss and squash the chip or something.

Quote from: alanp on October 12, 2020, 03:25:29 PM

CodeMonk, what are the Hakko codes for those? Do they affect your technique?

On the whole, I kinda like SMD. You don't have to clip fifty damn component leads, that's for sure! And if you want to fit a huge, complex circuit into something smaller than a shoebox, you kinda don't have much of an option.