JUANSOLO THAT IS AN AWESOME PHOTO

- Welcome to madbeanpedals::forum.

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

#2

Open Discussion / Re: WEENER 2-info-using the tone tank inductor and other notes

March 04, 2015, 09:29:11 PM

jimilee

ebay says it better than i ever could..... wait ! i wrote this stuff! ( don't buy on ebay, message me here if interested)

http://www.ebay.com/itm/NEW-TONE-TANK-wah-inductor-larger-coil-GREAT-TONE-patterned-after-famous-EL-RAD-/121585544549?ssPageName=STRK:MESE:IT

ebay says it better than i ever could..... wait ! i wrote this stuff! ( don't buy on ebay, message me here if interested)

http://www.ebay.com/itm/NEW-TONE-TANK-wah-inductor-larger-coil-GREAT-TONE-patterned-after-famous-EL-RAD-/121585544549?ssPageName=STRK:MESE:IT

#3

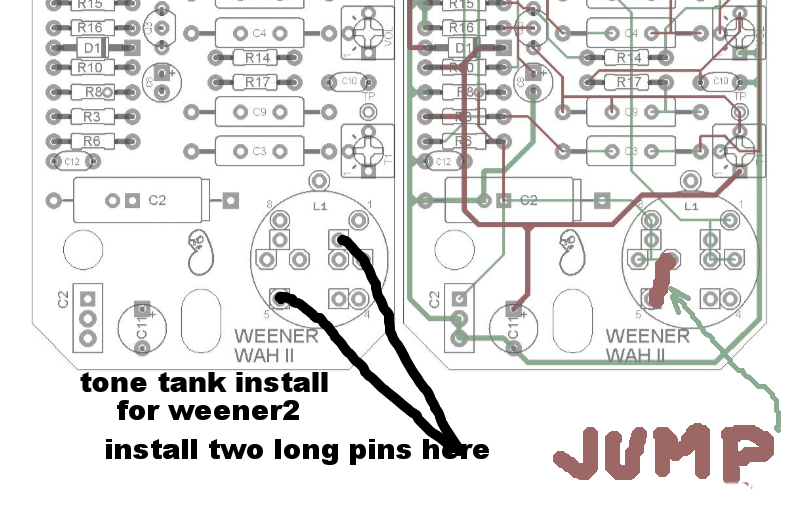

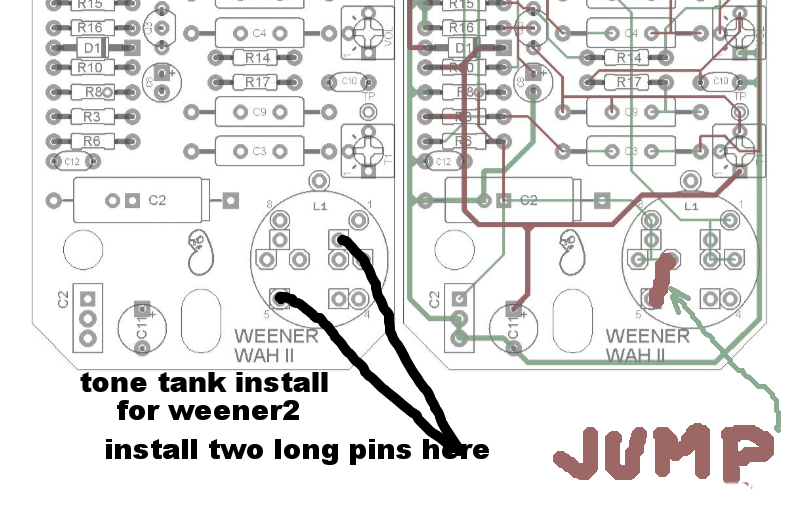

Open Discussion / WEENER 2-info-using the tone tank inductor and other notes

March 04, 2015, 07:30:08 AM

just took another look at the weener 2 board, i noticed you would need a jumper to make the dunlop inductor pinout work for the board. this note applies to most dunlop inductors from '90 to 2010, there was a 7.5mm two or four-pin layout, the hot leads are diagonal. my tone tank inductor uses the dunlop pinout since it was designed to retrofit into the million dunlops out there. jumper diagram below.

also, recently, it is possible that PPP is using a non-standard gear pattern for their wah shells. looking into it further this month. be aware, if you use my 50k, 100k , 250k or 500k smooth pot from my ebay store , small bear, or me directly, my gear may not mesh. removing my gear is easy but they are glued on so well the gear will be destroyed in the process. if you have a ppp shell and want to use a gagan pot , send me a message and i will leave the gear off or install it for you if you send it to me.

thanks! happy wahing.

also, recently, it is possible that PPP is using a non-standard gear pattern for their wah shells. looking into it further this month. be aware, if you use my 50k, 100k , 250k or 500k smooth pot from my ebay store , small bear, or me directly, my gear may not mesh. removing my gear is easy but they are glued on so well the gear will be destroyed in the process. if you have a ppp shell and want to use a gagan pot , send me a message and i will leave the gear off or install it for you if you send it to me.

thanks! happy wahing.

#4

Open Discussion / Re: Soldering Iron Broke. Need Recommendations

February 11, 2015, 10:47:52 AM

looking for a new one myself, thanks for the recommends.

a friend told me about this hakko knock-off, he bought it and likes it pretty well, great for the money.

http://www.ebay.com/itm/390635897189?_trksid=p2059210.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

ditto on the brass wool instead of wet sponge. i think the thermal shock of cooling the tip all the time wears the tips out faster.

a friend told me about this hakko knock-off, he bought it and likes it pretty well, great for the money.

http://www.ebay.com/itm/390635897189?_trksid=p2059210.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

ditto on the brass wool instead of wet sponge. i think the thermal shock of cooling the tip all the time wears the tips out faster.

#5

Open Discussion / Re: Trying to find a 50kB wah pot, help!

February 11, 2015, 10:40:59 AM

thanks guys!

i have 50k log and rev log in stock, with 13, or 14 tooth gears available. i don't exactly list them all on ebay , they are the ones we use for boomerang replacement ( rev log ) and faux boomers.

for vox shell and wah, you want log taper. in my 28 point measuring system in actual wah shell, the log taper with our 13 tooth gear is so close to ICAR it isn't funny. i recommend the 13 tooth, if you trim the rubbers a wee bit and lower the switch, you get 100% of the r range, unlike most icar type pots.

madbean members, $18 shipped gets it. my paypal is joegagan@hotmail.com

you can see the details on it at my ebay page.

http://www.ebay.com/itm/Replacement-Pot-for-Maestro-BOOMERANG-wahs-SUPER-Quality-/121197534404?ssPageName=STRK:MESE:IT

i have 50k log and rev log in stock, with 13, or 14 tooth gears available. i don't exactly list them all on ebay , they are the ones we use for boomerang replacement ( rev log ) and faux boomers.

for vox shell and wah, you want log taper. in my 28 point measuring system in actual wah shell, the log taper with our 13 tooth gear is so close to ICAR it isn't funny. i recommend the 13 tooth, if you trim the rubbers a wee bit and lower the switch, you get 100% of the r range, unlike most icar type pots.

madbean members, $18 shipped gets it. my paypal is joegagan@hotmail.com

you can see the details on it at my ebay page.

http://www.ebay.com/itm/Replacement-Pot-for-Maestro-BOOMERANG-wahs-SUPER-Quality-/121197534404?ssPageName=STRK:MESE:IT

#6

Open Discussion / Re: Alpha dpdt psa

February 08, 2015, 08:49:48 PM

cool tip, thanks. does anyone know of a quality difference between these and the similar daier switches?

davent, interesting point. on all of my ebay auctions i have unique ship to canada, since it costs me less.

i even charge less than my cost in some cases because i love canada. other Us ebay sellers should do same IMO.

davent, interesting point. on all of my ebay auctions i have unique ship to canada, since it costs me less.

i even charge less than my cost in some cases because i love canada. other Us ebay sellers should do same IMO.

#7

Open Discussion / Re: Joe Gagan pot/PPP wah enclosure compatibility problem + solution

January 30, 2015, 08:03:07 PM

thanks guys.

#8

Open Discussion / Re: Joe Gagan pot/PPP wah enclosure compatibility problem + solution

January 29, 2015, 10:25:00 PM

i asked aron to delete it specifically because of the first 5 words 'problem with a joe gagan... " that was the thread title. for people perusing google about my products , those are not good words to have come up, regardless of what the backstory is. many people will not dig any further into it. it harmed my online reputation for a reason that is not my problem.

i am not expecting preferential treatment here, i am sure any retailer/ supplier could have made the same request and had the same result. i find your claim to the contrary offensive.

i cannot be responsible for people selling rack gears that are not industry standard. mine are.

i cannot take the time to find out what fringe products are out there that mine may or may not work with.

1000 pots were sold with the 12 tooth gears, this is the first time in 20 months that anyone has mentioned that a rack gear is incompatible EXCEPT some 60s italian /UK wahs. for my ebay sales, i clearly state that if you have one of these wahs, to contact me for advice. i have different gears i sell for those.

so, while it may seem the mammoth and PPP are a major source of wah shells, my experience has been the opposite.

specifically about the various import shells that are being sold - it would do no good to try and nail down what rack gear those people are using because from what numerous sources have told me, the product varies in specs from one shipment to the next, even from the same supplier.

again, the reports i get from tom hughes of black cat and others is that the eleca shell for small bear is of very good quality and does not have the aforementioned issues.

i am not expecting preferential treatment here, i am sure any retailer/ supplier could have made the same request and had the same result. i find your claim to the contrary offensive.

i cannot be responsible for people selling rack gears that are not industry standard. mine are.

i cannot take the time to find out what fringe products are out there that mine may or may not work with.

1000 pots were sold with the 12 tooth gears, this is the first time in 20 months that anyone has mentioned that a rack gear is incompatible EXCEPT some 60s italian /UK wahs. for my ebay sales, i clearly state that if you have one of these wahs, to contact me for advice. i have different gears i sell for those.

so, while it may seem the mammoth and PPP are a major source of wah shells, my experience has been the opposite.

specifically about the various import shells that are being sold - it would do no good to try and nail down what rack gear those people are using because from what numerous sources have told me, the product varies in specs from one shipment to the next, even from the same supplier.

again, the reports i get from tom hughes of black cat and others is that the eleca shell for small bear is of very good quality and does not have the aforementioned issues.

#9

Open Discussion / Re: wah mechanicals, tips and tricks

August 20, 2014, 02:20:49 PMQuote from: wgc on August 20, 2014, 12:00:20 PM

Yeah, you'll have a hell of a time rotating this while it's still pressed in. I use the way you described below.

Also if you trim the pads you might want to lower your switch height a little bit too.

Might go without saying, but just in case: Loosen the switch outside nut a bit farther than you want, then raise the inside nut to the height you want. Tighten the outside nut, and check. It may take a few times to get it where you want it but its not that hard.

agree 100%

also, great tips on switch height. i also spin the inner nut UP to the height from the inside. you can get really close to the final height while switch is loose, if you set the outer nut to where the switch switches VERY hard by hand, then raise the inner nut up tight, the final tightening of the outer nut gets a really good setting.

*you can even use a tiny screwdriver and little hammer to tap the inside nut into a tight position, place the screwdriver on the outer edge of the nut side)

#10

Open Discussion / Re: wah gear mechanicals

August 20, 2014, 04:17:11 AMQuote from: wgc on August 20, 2014, 03:53:37 AM

I've seen some improvement by rotating the pin (63) 90 deg or so. Sometimes they develop a flat spot where it hits the flat spring underneath. Also you get a little more travel if you trim some height off the rubber stops near the switch.

awesome, those are both great tips. i assume you back the axle out of its hole past the knurl to rotate.

for removing the axle on wah:

1. loosen the tensioner strap as loose as you can, but leave the nuts on the screws, no need to remove them.

2. get the wah resting sideways on cloths and wood shims to avoid scratching. identify where the axle knurl is so you tap the axle OUT the reverse direction it went IN.

3. use a proper ' drift' or punch of slightly smaller than axle diameter. make one out of a quality bolt or hinge pin if necessary. the diameter is important - too small has a tendency to ' mushroom' the axle in it's hole.

4. don't hammer too long - if it doesn't come out easy stop and try a little PB blaster or other penetrating oil to loosen it up. if you use these be sure and remove any trace of it with alcohol or lacquer thinner before reinserting axle.

5. double or triple layers of duct tape surrounding the axle hole will prevent finish chipping/ marring if you slip while driving the axle back in. you may also find the same drift that removed the axle is helpful in the last few hammer blows getting the axle seated back in it's holes.

similar rules apply for removing the little pin that holds the rack gear. first, use a pair of channellocks set to a proper jaw opening to push the pin flush with standoff, then use a specially prepped punch, again just barely smaller than the pin - i use a cut off eyeglass screwdriver with the end ground blunt for proper pushing and a very slight taper to prevent it getting stuck in the hole. once the pin is sticking out a few mm, you should be able to gently grab it and pull straight out. do not twist, as this usually just goes to crap.

i often use the channel locks to also push & reset the pin after swapping the rack gear.

note on the tensioner spring bolts: on certain mid 80s to early 90s dunlops, the shell castings were thin, causing the tension to bow the shell metal toward treadle at the screw heads. use a couple stacked fender washers to spread the load out and allow proper tension on those screws if needed.

#11

Open Discussion / Re: PSA regarding Tayda Alpha rotary switches

August 19, 2014, 11:01:39 PMQuote from: davent on August 19, 2014, 02:38:24 PM

Not sure about the Alpha switches but at least with pots and Hammond enclosures you can drill deep to engage a shortened nub, without drilling through the enclosure.

i use a couple round head dremel cutters. here is an alpha with the tab in my modded BBE wah

#12

Open Discussion / wah mechanicals, tips and tricks

August 19, 2014, 10:06:45 PM

below is a little photo essay on getting a nice smooth action from your wah. almost all the wahs i sell do not have any lube and work great.

sometimes it becomes necessary to move the pot toe-ward or heel-ward to improve the geometry. seems especially true with at least some of the chinese made wah shells lately, especially when my smaller gear is used( in some cases the action was improved by moving the pot as far heel direction as possible, even flattening the bushing of the pot to move it further rearward). the quality of the chinese shells has been very sporadic both in machining accuracy and the way parts align etc.

please add your input , i hope this thread can become a good resource for all things wah/mechanical.

also, i am on facebook at ' wah wah by joe gagan' --- please come and share your experiences there as well if you have time!

sometimes it becomes necessary to move the pot toe-ward or heel-ward to improve the geometry. seems especially true with at least some of the chinese made wah shells lately, especially when my smaller gear is used( in some cases the action was improved by moving the pot as far heel direction as possible, even flattening the bushing of the pot to move it further rearward). the quality of the chinese shells has been very sporadic both in machining accuracy and the way parts align etc.

please add your input , i hope this thread can become a good resource for all things wah/mechanical.

also, i am on facebook at ' wah wah by joe gagan' --- please come and share your experiences there as well if you have time!

#13

Open Discussion / Re: No experience with Vox wah - feedback please

January 06, 2014, 05:33:20 AM

the factory document that first mentions dunlop for vox wah is 'rev A' and has a 93 date.

cool, i never saw this one. it mentions the type of dunlop inductor spec and other cool stuff:

http://www.voxamps.com/downloads/circuits/wahwah93.jpg

cool, i never saw this one. it mentions the type of dunlop inductor spec and other cool stuff:

http://www.voxamps.com/downloads/circuits/wahwah93.jpg

#14

Open Discussion / Re: No experience with Vox wah - feedback please

January 06, 2014, 03:40:27 AM

3 major variants floating around. not sure what vox was making prior to dunlop taking over mfgring them in late 80s or early 90s, but here are the three types , from then to now:

1. dunlop made v847 , 80s or 90s , possibly into early 2000s, - two transistor, no power supply input hotpotz1 or hotpotz2 after around 95-ish. the hotpotz2 got a snazzy aluminum cylinder cover on the pot, unique to the voxes. they sound damn good stock and are ripe for modding since the board is very close to the 60s vox classic wah (no buffer or board mount jacks etc).

2. sometime after 2000, they just gave up and made the voxes the same as 3 trans gcb95 dunlops. power supply input etc. pretty rare.

3. post 06 or 07 , the vox company moved production to china. these are called V847a, can be distinguished from the US made ones without opening the pedal by the rectangle power supply jack hole on the output jack side. savvy sellers avoid showing that side to make buyers think they might be getting a US one. these sound pretty good also, the inductors are pretty nice, but the pots SUCK and there are tons of smd parts under the board, making modding really tricky, compared to US made 2 trans models.the v847a has an input buffer and is not true bypass.

they came out with an all black, no chrome budget model in the china series called v845, which is similar to the 847a , but with no buffer, back to the 2 trans! ha! same board and smd extra parts as the 847a.

all chinese voxes have stand alone jacks.

the shells are nice and light on these, possibly alum as opposed to zinc, so lighter to ship.

the v845 is a nice candidate for making your own wah if you can find one for 25 used, but also be warned that the PCB mounting holes are not the same as the classic dunlop vox/ crybaby shells.

1. dunlop made v847 , 80s or 90s , possibly into early 2000s, - two transistor, no power supply input hotpotz1 or hotpotz2 after around 95-ish. the hotpotz2 got a snazzy aluminum cylinder cover on the pot, unique to the voxes. they sound damn good stock and are ripe for modding since the board is very close to the 60s vox classic wah (no buffer or board mount jacks etc).

2. sometime after 2000, they just gave up and made the voxes the same as 3 trans gcb95 dunlops. power supply input etc. pretty rare.

3. post 06 or 07 , the vox company moved production to china. these are called V847a, can be distinguished from the US made ones without opening the pedal by the rectangle power supply jack hole on the output jack side. savvy sellers avoid showing that side to make buyers think they might be getting a US one. these sound pretty good also, the inductors are pretty nice, but the pots SUCK and there are tons of smd parts under the board, making modding really tricky, compared to US made 2 trans models.the v847a has an input buffer and is not true bypass.

they came out with an all black, no chrome budget model in the china series called v845, which is similar to the 847a , but with no buffer, back to the 2 trans! ha! same board and smd extra parts as the 847a.

all chinese voxes have stand alone jacks.

the shells are nice and light on these, possibly alum as opposed to zinc, so lighter to ship.

the v845 is a nice candidate for making your own wah if you can find one for 25 used, but also be warned that the PCB mounting holes are not the same as the classic dunlop vox/ crybaby shells.

#15

Build Reports / Re: Fiery RedHead, my take on the Weener (Mojo content, be warned!)

November 09, 2013, 05:14:52 PM

wow, looks gorgeous. really impressive work there. honored to be involved for sure. realy nice job on the red finish , also looks great contrasting the carved rubber pad.

looking forward to hearing the clipz!

looking forward to hearing the clipz!