Bench update . . . .

With the TLE2074 removed:

1) pins 12 & 13 now read 4.88 volts - but pin 1 reads only 1.2v.

2) unable to measure the 2M2Ω resistor between pins #12 & #5 of the socket - but there is continuity between pin 12 and the 2M2Ω resistor; there is also continuity between pin 5 and VB - AND continuity between the other side of the 2M2Ω resistor and VB.

3) the 2M2Ω resistor measures 2.2M Ω (with the TLE2072 out of the socket.

On the SB3 board:

1) R5 & R6 are in place

2) C6 is installed reverse of the PCB markings (as per the build doc)

3) there is ~4.88 volts on the V- point and ~9v on the V+ point

Other points:

1) all 3 16mm pots have SmallBear pot condoms on them

2) with all chips in place, powered up and plugged in, all the controls have functionality. The output is just quite distorted. (The first opamp [TLE2074] section has a low-voltage condition on pins 12, 13 & 14.)

3) C18 (.22µF) is not leaky (from Mouser)

4) C12 (10µF BP) is not leaky (from Mouser)

5) Tried a few different quad opamps (TL074, TL084, OPA4134 & OPA4132) and all exhibit the same low voltage on pins 12, 13 & 14 - and all the pots still have functionality - just dirty output

6) With all chips in place and the circuit powered up, there is 4.88v at the VB points, including pin 5 of the TLE2074

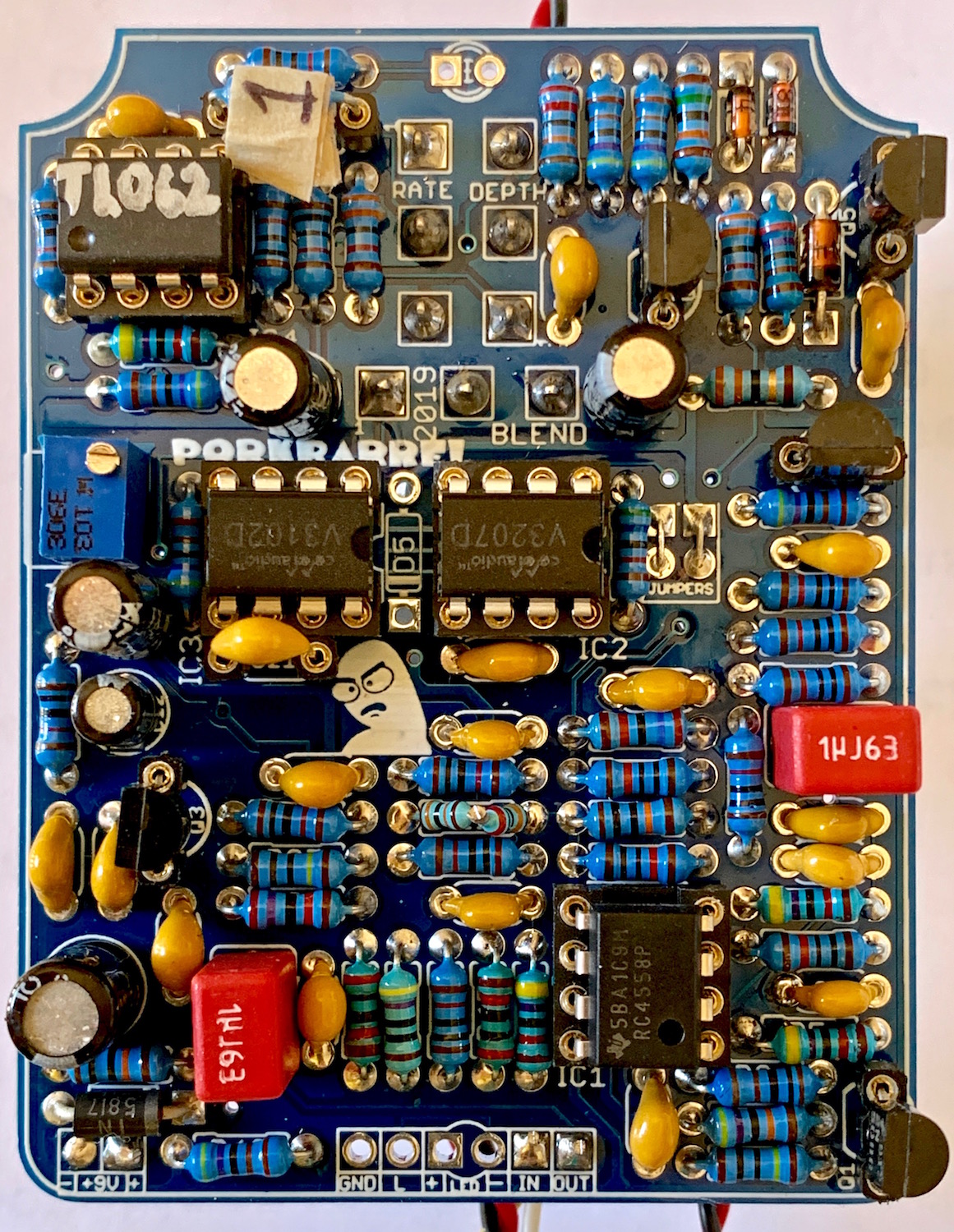

I've not started pulling my hair out yet, but it's close to that pointless prospect. Clear photos coming shortly.

Any further suggestions or things to check will be appreciated.

With the TLE2074 removed:

1) pins 12 & 13 now read 4.88 volts - but pin 1 reads only 1.2v.

2) unable to measure the 2M2Ω resistor between pins #12 & #5 of the socket - but there is continuity between pin 12 and the 2M2Ω resistor; there is also continuity between pin 5 and VB - AND continuity between the other side of the 2M2Ω resistor and VB.

3) the 2M2Ω resistor measures 2.2M Ω (with the TLE2072 out of the socket.

On the SB3 board:

1) R5 & R6 are in place

2) C6 is installed reverse of the PCB markings (as per the build doc)

3) there is ~4.88 volts on the V- point and ~9v on the V+ point

Other points:

1) all 3 16mm pots have SmallBear pot condoms on them

2) with all chips in place, powered up and plugged in, all the controls have functionality. The output is just quite distorted. (The first opamp [TLE2074] section has a low-voltage condition on pins 12, 13 & 14.)

3) C18 (.22µF) is not leaky (from Mouser)

4) C12 (10µF BP) is not leaky (from Mouser)

5) Tried a few different quad opamps (TL074, TL084, OPA4134 & OPA4132) and all exhibit the same low voltage on pins 12, 13 & 14 - and all the pots still have functionality - just dirty output

6) With all chips in place and the circuit powered up, there is 4.88v at the VB points, including pin 5 of the TLE2074

I've not started pulling my hair out yet, but it's close to that pointless prospect. Clear photos coming shortly.

Any further suggestions or things to check will be appreciated.

??

??